Product Driven. Customer Focused.

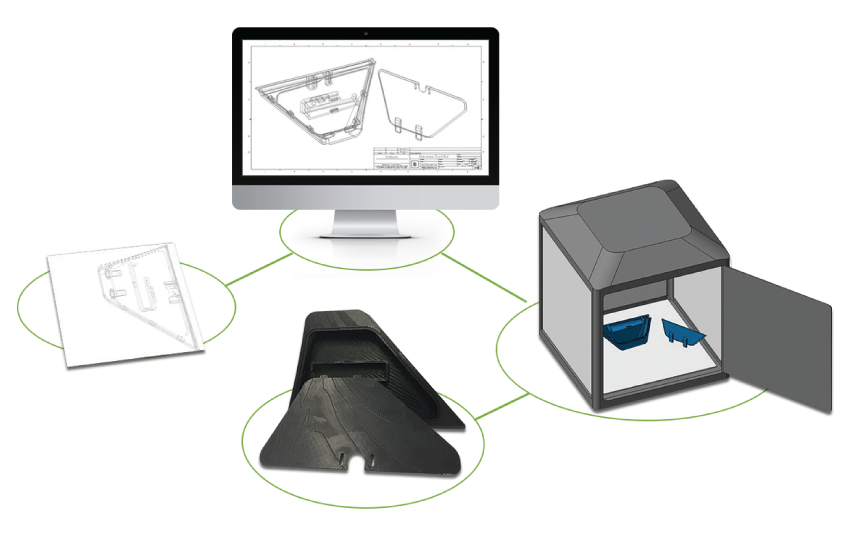

Our 3D Checkpoint Process

Our 3D Checkpoint process has been designed with ultra high precision that can be expected at every level to support client success. The 3D Parts advantage includes seamless product development and delivery from design to final product that meets or exceeds all project requirements. Your product is our passion, we deliver results through a “product driven” approach; from a 24-48 hour estimate turnaround time to full 3 dimensional replication to the delivery of your final product.

Mission Statement

We are the innovative and revolutionary provider of plastic parts and tooling, delivering prototype and production solutions from inception to product realization.

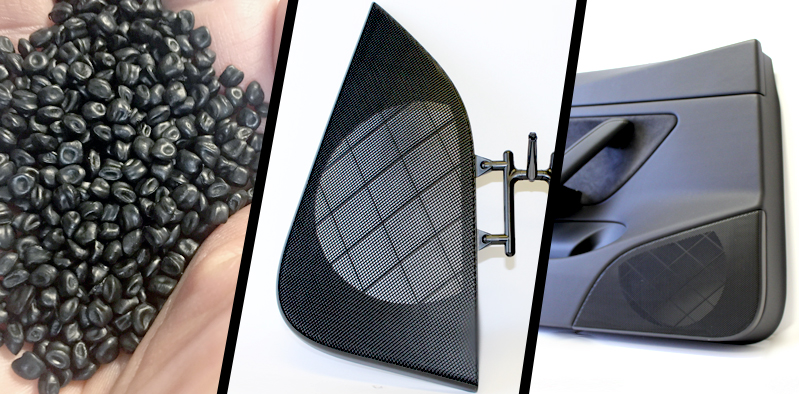

Automotive

Speed, quality, and precision is what drives our success.

Consumer Products

Products designed and manufactured for everyday use.

Aerospace

3D Checkpoint process builds three dimensional solid objects allowing you to fly to greater heights.

Innovation

Serving many existing markets and using creative thinking, 3D Parts can create whatever you need.

About Us

We deliver results through a “product driven” approach, based on enhanced collaboration and cooperation with your team. Nimble and adaptive, we respond to your needs with our iterative approach (3D Checkpoints) throughout the product life cycle. We ensure all aspects and elements are addressed to achieve better quality, increased collaboration and increased speed from concept to finished product. We are the solution to your most complex challenges!

What We Do

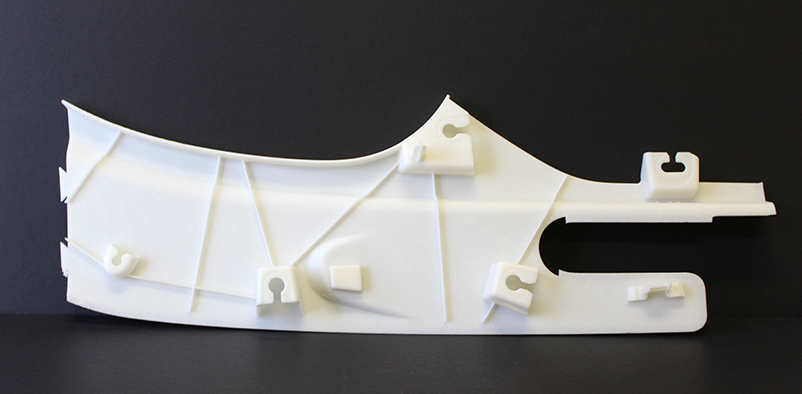

Utilizing your design data and specifications, we can quickly create manufactured plastic prototypes from the most applicable technology, ensuring you get the realistic 3D part in hand in a timely manner.

RAPID PROTOTYPING

Our unique process that allows you to take your project from initial concept to a fully manufactured product, quickly and with quality at the forefront through each process.

MANUFACTURING

With 3D Parts technology and advanced thermoforming techniques, our company is capable of producing production injected molds with superior materials in-house.

INJECTION MOLDING

Equipment Capabilities

3D Parts utilizes state-of-the-art technologies and equipment to ensure fast and accurate prototype and production parts.

Our clients

… and more! Thank you for your continuing support!